Contourfive NC 700/1200 - CNC milling centre with 5 interpolated axes designed for cutting, contouring and turning operations

Contourfive is a numerical control machining centre with five interpolated axes for machining pieces made from marble, granite, compound stone and stone in general.

Top structural stiffness and accessibility

Floor-anchored shoulders made from either masonry or (on request)heavy-duty metallic structure ensure a top structural stiffness of the system. The excellent accessibility to the working area is guaranteed by the worktable which is separated from the lateral shoulders and stiffly anchored to the floor, so that the operator can easily approach it from all sides, with no steps to mount. The height of the worktop of 500mm (19.7") plus the height of the suction cups of 230mm (9"), enables an easy handling of the machined tops.

Top structural stiffness and accessibility

Floor-anchored shoulders made from either masonry or (on request)heavy-duty metallic structure ensure a top structural stiffness of the system. The excellent accessibility to the working area is guaranteed by the worktable which is separated from the lateral shoulders and stiffly anchored to the floor, so that the operator can easily approach it from all sides, with no steps to mount. The height of the worktop of 500mm (19.7") plus the height of the suction cups of 230mm (9"), enables an easy handling of the machined tops.

Thanks to its vertical travel of 700/1.200mm, Contourfive is the ideal machine for architectural and funerary art as well as for those processing which require a deep dishing out; it therefore offers the users the possibility of performing different and complex machining operations which would otherwise require several machines::

• shaping utilising the saw blade to get large pieces with complex shape.

• shaping and dishing out utilising millers.

• contouring utilising shaping tools.

• sawing utilising the saw blade.

• turning of columns with shaped profiles or machining of columns to create a twisted effect all along the surface (provided the lathe accessory is purchased).

Contourfive stands out for performance:

• short beam ensuring maximum rigidity;

• “rapid” displacements of up to 40 metres per minute;

• powerful high-frequency spindle of 27/46HP;

• max. diameter of the cutting saw blade: 19.7/31.5/39.4"

• “C” axis rotation: ± 200°;

• “A” axis rotation: from 0° to +115°;

• “X” axis travel: 145.5/141.7/137.7";

• “Y” axis travel: 110";

• “Z” axis travel: 27.6/47.2";

• possibility of using various saw blades, shaped tools, drills, millers, etc.;

• automatic tool-store with 27 positions + (optional) position for the saw blade.

Contourfive stands out for its structural features:

• High-speed, 27/30/46HP electrospindle featuring a rotation speed of up to 14.500/7.500/7.000rpm; it is provided with thermal stability and long-life grease lubrication of the bearings. The tool coolant flows inside the spindle.

• Birotary head for interpolated 5-axis machining. The head has a symmetrical structure and consists of two main structural elements, the first (“C” axis) is fitted for ± 200° rotation around its own vertical axis and the second element (“A” axis) rotating from 0° to +115° and housing the high-frequency spindle.

Rotation transmission are provided by brushless-type motors.

• Iron casting spindle-holding carriage running on roller slides ("X" axis) and actuated by a precision pinion-and-rack system, which is motorized by a digital brushless motor. The spindle-holding steel ram ("Z" axis) is vertically housed in the carriage; the ram moves through a ball bearing screw/preloaded lead nut/ digital brushless motor system. The position monitoring is performed by the motor encoder.

• Steel work-table secured to the ground, with aluminium top with recesses for mounting fixtures to secure the work piece in place.

• Beam with “gantry” movement along the shoulders (“Y” axis) on ground guides; is through a pinion-and-rack system and precision reducers with backlash adjustment, driven by digital brushless motor.

• Mobile 27-cell carrousel tool-store for tool-holders, to automatically change tools other than the saw blade.

• Store for saw blade with a max. diameter 19.7" (STANDARD version), 23,6" (HD version), 39,4" (SHD version) (optional).

• Lathe for producing columns and twisted effect details with workable sizes: ø37.8/63x126" - optional accessory.

• Frontal protection barrier consisting of a series of sliding doors with manual opening; doors are made from structure and are provided with wide inspection ports.

• Siemens Sinumerik 840 SL: the latest digitally-controlled computer numerical control system, with PC architecture and a PC unit utilising Windows as operating system, with Windows user-friendly interface and fully-developed software for work program management.

• Control console mounted on a mobile pendant structure and equipped with a 15-inch touch-screen colour monitor, a joystick to easily move the motorized working axes movement and a USB port for data transfer.

• Portable mini console, wired to the main control console, to duplicate the major controls (axes management + hand-wheel, emergency shut-down, etc.); this portable mini console allows the operator to be close to the piece to be machined thus controlling directly some delicate machining operations.

• Electrics and utilities are housed in two cabinets with IP54 grade of protection and cooled by an air conditioning unit specially designed for a maximum external temperature of +45°C.

Top structural stiffness and accessibility

Floor-anchored shoulders made from either masonry or (on request) heavy-duty metallic structure ensure a top structural stiffness of the system. The excellent accessibility to the working area is guaranteed by the worktable which is separated from the lateral shoulders and stiffly anchored to the floor, so that the operator can easily approach it from all sides, with no steps to mount. The height of the worktop of 350mm (13.8") plus the height of the suction cups of 230mm (9"), enables an easy handling of the machined tops.

Breton Teleservice

A Internet connection is required in order to ensure an effective technical support in case of need.

Software for simulating work cycle

This software has been developed to simulate Contourfive when working by dividing the machining centre into different parts: machine structure, axes, spindle, tool-store, tools. The software imports the file generated by the CAM program (ISO code) for the piece to bemachined and simulates the entire machining cycle,thus detecting any possible impact which may occur.

Wide choice of software (optional)

Breton offers a wide choice of software – which are customized according to the single users’ requirements - for the CAD/CAM programming of their shaping, cutting and turning centres with several controlled and interpolated axes.

Thanks to Breton’ software, such numerical control centres make the most of their technological potentials, and execute the widest and most fanciful range of machining for interior design, architectural and funerary art.

All software operate in a Windows environment, are easy-to-understand and user-friendly thanks to the parametric macros, which enable to execute drawing s in a simplified way starting from standard parametric models.

Breton’ skilled officers will be at your disposal to show you demos of the different options so as to choose the most suitable software.

Accessories

• Lathe for producing columns and twisted effect details with workable sizes: ø37.8/63x126" - optional

• Automatic tool control (optional).

It consists of a laser system for measurement to hundredths of the tool profile (installed on a shoulder of the machine) and of a software that automatically aligns the profiles of the series of tools that polish the edge. This software can also check the consumption and efficiency of each tool.

• Suction cups with mechanical locking H=9 in. (optional).

• Store for saw blade with a max. diameter of 500mm (19.7"), 600mm/23.6" (for HD version) or 39.4" (SHD version) secured to the side shoulders (optional).

• 3D detection of the piece

This is a precision 3D “laser scanner” optical system that, without contact, detects the shape and dimensions of the piece to be copied. The powerful management software enables you to copy complex, three-dimensional surfaces by creating their shape and programs the milling operations with graphic simulation in order to check in advance the final result. (optional).

• “Laser” projector of the piece and suction cup shapes

It is a “laser” projector mounted on a special support stand, that makes the positioning of the vacuum pads on the work table easier for the operator through the projection on the table surface of the shape of both the piece to be produced and the single vacuum pad to be prearranged. The laser projector is controlled by the computer-aided system. (optional).

• Steel frame also available (optional)

• Measurement “by contact” of the surface

It is a device that measure “by contact” with radio transmission the correct spatial position of the planes to be worked. The machine is equipped with software that enables the working tool to follow accurately the surface. It is “essential” to carry out drainboards on slabs not perfectly calibrated or to process edges with the slab polished face upwards. (optional).

Layout - overall dimensions

Technical specifications

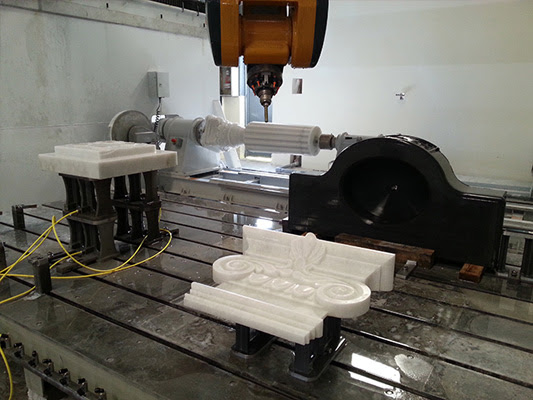

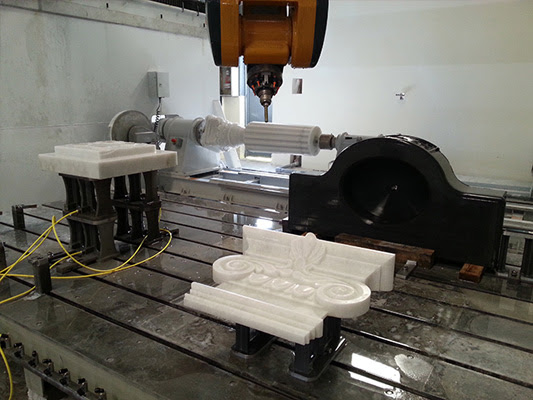

Here you can find the stone working centre Contourfive NC 700 with 5 interpolated axes while is realizing several pieces.

It's all for today.

Bye-bye

Sergio Prior